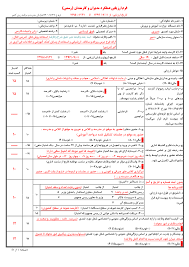

Just—in-Time Inventory and Production Management

A just -in-time (J1T) inventory and production management system is

a comprehensive i9entorv and manufacturing control systen1in which no materials are purchased and no product s are manufactured until they are needed. Kaw materials and parts are purchased only as the arc needed in some phase of the production process. Component parts and subassemblies are not manufactured in any stage of production until they the next stage. Finished goods are manufactured only as t hey arc needed to fill customer orders. A primary goal of a J IT production system is to reduce or eliminate inventories at every stage of Production, from raw materials to finished goods. The JIT philosophy, made famous by Toyota, has been credited with the success of many of the world's leading manufacturers. Tremendous cost savings have been realized by many companies that have adopted the ,JIT approach.

J1T COS’I’ SAVINGS: INGERSOLL-RAND NAD 1NEYWELL

In a large-scale installation of JIT Systems by Ingersoll-Rand, the company saved $3,500,000. The installation of a J1T production system in on1y one of 10 production lines at Honeywell's Process Control Division netted cost -savings of $26,0011.

1. A smooth, uniform production rate. An important goal of a JIT system is to establish a smooth production flow, beginning with the arrival of materials from, suppliers and ending with the Delivery of goods to customers. Widely fluctuating product ion rates result in delays and excess work – in-process inventories. These non—value—added costs are to be eliminated.

2. A pull method of coordinating steps in the production process. Most manufacturing processes occur in multi pie stages. Under the pull method, goods are produced in each manufacturing stage only as they are needed at the next stage. This approach reduces or eliminates work—in- process inventory between production steps. The result is a reduction in waiting time and its associated non-value-added cost.

The pull method of production begins at the last stage of the manu facturing process. When additional materials and parts are needed for fi nal assembly, a message is sent to the immediately preceding work center to send the amount of materials and parts that will be needed over the next few hours. Often this message is in the form of a withdrawal Kanban, a card indicating the number and type of parts requested from the preceding work center. The receipt of the withdrawal Kanban in the preceding work center triggers the release of a production Kanban, which is another card specifying the number of parts to be manufactured in that work center. Thus, the parts a me “pulled” from particular work center by a need for parts in the subsequent work center. This pull approach to production is repeated all the way up the manufacturing sequence toward the beginning. Nothing is manufactured at any stage until its need is signaled from the subsequent process via a Kanban. As a result, no parts are produced until they are needed, no inventories build up, and the manufacturing process - exhibits a smooth, uniform flow of production .

3. Purchase of materials and manufacture of subassemblies and products in small lot sizes. This is an outgrowth of tile pull method of production planning. Materials ire purchased and goods are produced only as required, rather than for the sake of building up stocks, The result is a red acion in storage and waiting time. And the related non—value—added costs.

4. Quick and inexpensive setups of productional machinery. In order to produce in small lot sizes, a manufacturer must he able to set up pro- duction runs quickly. Advanced manufacturing technology aids in this process. as more and more machines are computer-controlled.

5. High quality levels for raw material and finished products. If raw materials and parts are to arrive ‘just in time” for production. they must be "just right” for their intended purpose. Otherwise, the production line will be shut down and significant non-value-added costs of waiting Will result Moreover, if very small stocks of finished goes are to he maintained. then finished products must be of uniform high reality. For this reason, a total quality control for TQC program often accompanies a just -in-time production environment.

6. Effective preventive maintenance of equipment. If goods are to be manufactured just in time to meet customer orders. A manufacturer can not afford significant production delays. By strictly adhering to routine maintenance schedules. the firm can avoid costly clown time from machine breakdowns.

7. An atmosphere of teamwork to improve the production system. A company can maintain a competitive edge in today's worldwide market only if it is constantly seeking ways to improve its product or service, achieve more efficient operations, and eliminate non-value-added costs. My favorite football coach often says that a team must improve from one week to the next. Otherwise the team will get worse, because it rarely will stay at the same level. So it goes in business as well. If a company's employees are not constantly seeking ways to improve the firm’s performance, before long its competitors will pass it by. Many organizations encourage employees to make suggestions for improvement. Rewards are given when cost- saving suggestions arc implemented.,

8. Multiskilled workers and flexible facilities. To facilitate just-in-time production, manufacturing equipment must be flexible enough to produce a variety of components and products. Otherwise, if a particular production line can produce only one item, bottlenecks may result. A bottleneck can hold tip production in subsequent manufacturing stages and result in the non-value-added costs associated with waiting time. As high-tech production equipment becomes more versatile, production employees must be Capable of handling a variety of machines and operations. By grouping machines into eel/s that produce a variety of items requiring similar production technology, multiskilled workers are able to operate several machines. This approach is called group technology.

JIT Purchasing In addition to a JIT product ion approach. Aerotech implemented JIT purchasing in its Bakersfield plant . Under this approach. materials and parts are purchased from outside vendors only as they are needed. This avoids the costly and wasteful buildup of raw-material inventories. The following are five key feat tires of JIT purchasing.

1. Only a few suppliers. This results in less time spent on vendor relations. Only highly reliable vendors are used, who deliver high—quality goods on time.

2. Long-term cortracts. Negotiated with suppliers. This eliminates costly paperwork and negotiations with each individual transact ion. The need for delivery can be communicated via a telephone call or computer message. The long term contract stale the price. quality, and delivery terms of the goods.

3. Materials and parts delivered in small lot sizes immediately before they are needed. This is the essence of the just-in-time philosophy Costly inventories are avoided by having supplies arrive “just-in-time" to be laced into production.

4. Only minimal inspection of delivered materials and parts. The long-term contacts clearly state the quality of material required. Vendors are selected on the basis of their reliability in meeting these stringent standards and in delivering the correct amount of materials on time.

5. Grouped payments to each vendor. Instead of paying for each delivery payments are made for batches of deliveries according to the terms of the contract. This reduces costly paperwork for both the vendor and the purchaser.

JIT purchasing is widely used in a variety of organization. In manufacturing firms. if goes hand in hand with JIT production. In retail and service industry firms, JIT purchasing reduces costly warehouse inventories and streamlines the purchasing function.

منبع : سايت علمی و پژوهشي آسمان -- صفحه اینستاگرام ما را دنبال کنید

اين مطلب در تاريخ: دوشنبه 22 دی 1393 ساعت: 18:19 منتشر شده است

برچسب ها : Just—in-Time Inventory and Production Management,

را بنویسید.

را بنویسید.

.png)

_285282.jpg)